Available Methods and Accessories

- Sensitive DSC that removes the risk of generating false data signals

- Modulated DSC (MDSC) capability that is required to detect complex material transitions

- Superior high throughput testing. The DSC X3 model contains both a 54 pan autosampler and the capability to acquire three DSC runs at the same time.

Sample Requirements

- Solid or liquid samples, standard size (5- 15 mg)

- Depending on type of Measurement: Typical Sample Size (mg)

- Purity: 1 to 3mg

- Melting point: 2 to 10mg

- Glass transition: 10 to 20mg

- Oxidative induction time (OIT): 10 to 25mg

- Melting and crystallization: 5 to 1mg

Detection Limits

- Temperature Range: -160 to 450 °C

- Temperature Accuracy and precision: +/- 0.005°C

- Controlled Heating Rate: 0.1 to 100 °C/min

Summary of Technique

- Understanding a material’s structure–property relationship is necessary when designing, processing, and utilizing a product. Differential Scanning Calorimetry (DSC)—measures endothermic and exothermic processes and is widely used to characterize a broad range of materials including polymers, pharmaceuticals, foods, biologicals, organic chemicals, and inorganic materials.

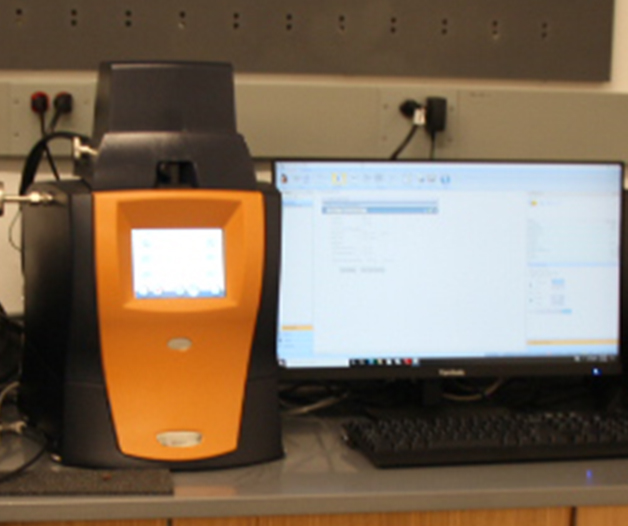

- The Discovery DSC X3 is a multi-sample differential scanning calorimeter allowing the simultaneous analysis of up to three samples. This provides unmatched flexibility from replicate testing for statistical analysis to validation/verification against a control sample for the ultimate in certainty.

- The DSC X3 is connected to liquid nitrogen cooling accessories and have a temperature range of -160°C to 450°C.

Information Provided

- DSC is a very powerful technique that easily measures thermal events such as the glass transition (Tg), melting, crystallization, cure reactions, onset of oxidation, and heats of transitions (enthalpy). Then expand upon the measurement of DSC Heat Flow to determine reaction kinetics, specific heat capacity, compatibility and stability of blends and alloys, effect of aging, impact of additives on crystallization, and much more.

- Modulated DSC capability. MDSC increases the amount of information that can be obtained from a single experiment.

- In addition to transition temperatures, melting and crystallization and heat capacity, modulated DSC provides an improved resolution of transitions that overlap or occur only a few degrees apart, an increased sensitivity to weak transitions, and separation of reversing and non-reversing phenomena.

Lab Location and Contact Information

Lab Location: Science 1 Research Center

Lab Manager: Dennis Ndaya

dennis.ndaya@uconn.edu

860-486-4075

Industrial Affiliates are encouraged to contact

IAP Director Paul Nahass paul.nahass@uconn.edu

or Assistant Director Hatice Bodugoz-Senturk Hatice.Bodugoz_Senturk@uconn.edu