from the Department of Materials Science and Engineering

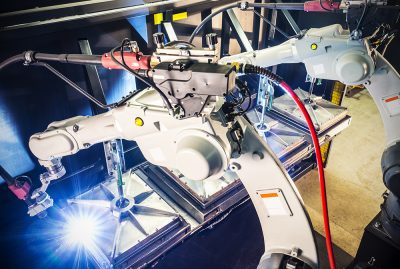

UConn recently received $10.5 million from the Air Force Research Laboratory (AFRL) for research on high-temperature materials and manufacturing processes. The funding will allow a team of seven faculty members from Materials Science and Engineering (Professors Aindow, Alpay, Frame, and Hebert), Civil and Environmental Engineering (Professor Kim), Mechanical Engineering (Professor Bilal), and Chemistry (Professor Suib) along with post-doctoral associates and graduate assistants to address challenges in the manufacturing of aerial systems intended to fly at high speed. Much of the four-year research project will focus on welding-related challenges for high-temperature metallic materials that are used for structures exposed to high speeds. The UConn team will combine experimental and theoretical approaches to help their collaborator, RTX, advance their manufacturing solutions. Additional project tasks address the behavior of non-metallic high-temperature materials under different processing and service conditions, additive manufacturing of high-temperature refractory metals, and the design and processing of metamaterials. These metamaterials are designed to change heat- and electro-magnetic fields in and around structures and are considered to advance the thermal management of high-temperature structures.

The new AFRL project comes at the heels of previous and ongoing AFRL projects for UConn approaching $30 million that involve over 15 faculty members from the Colleges of Engineering and Liberal Arts and Sciences with dozens of graduate students and post-doctoral associates. Covering research from functional materials and photonics to casting, welding, and additive manufacturing, the UConn team has established itself as a valuable partner for the AFRL and key industry partners, for example, Pratt & Whitney and Collins Aerospace.

Professor Rainer Hebert says of the contract, “The AFRL funding enables the UConn team to pursue materials processing research with a strong focus on industry and government relevance. Students and post-doctoral associates working on the project see firsthand how their research translates to industry. This insight will help in preparing a workforce that can pursue research excellence with a keen sense of the needs and constraints of industrial applications.”